MINSK MOTOR PLANT Minsk Service Manual Page 81

- Page / 97

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

245S3A М – 0000100 РЭ

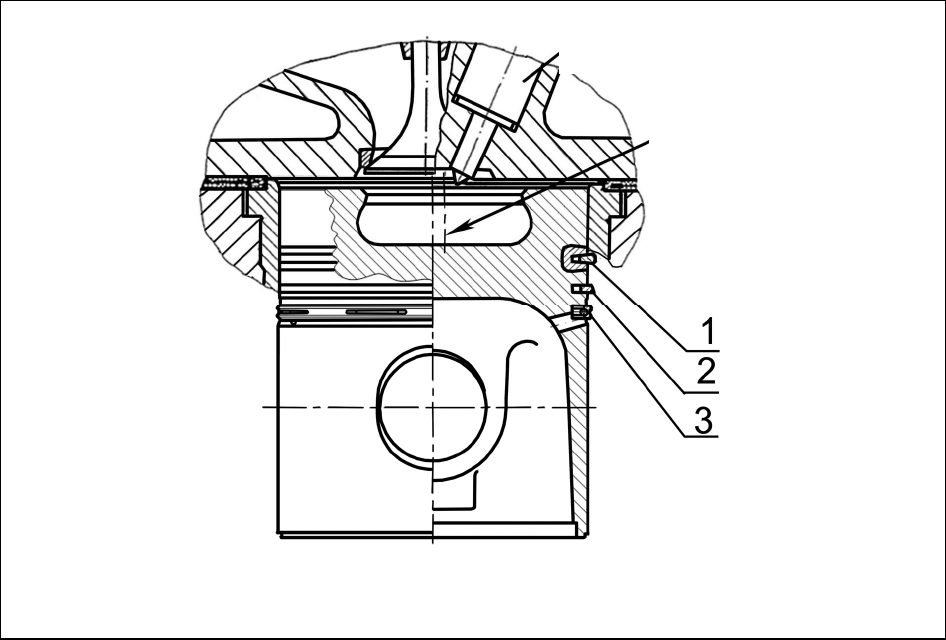

Piston ring locks shall be positioned at equal distance round the circle.

Put the piston-rod group inside the cylinder, mount the rod cover.

To prevent piston rings from damages by piston-rod group installation inside the

cylinder, use a tool for ring pinching.

Torque value of piston cover attachment nut is given in table (Annex D).

Figure 25- Diagram of piston rings installation

4.2.2 Main instructions on valve grinding

Unscrew attachment nuts of rocker arm shaft bracket and dismantle rocker arm shaft

with springs and rockers.

Unscrew head attachment bolts, remove the head.

Remove the cotter from the valve, take off the plate of valve springs, valve springs,

washers of valve springs; remove the sealing cup from the valve guide.

The valves shall be ground on special machines of ОПР-1841А type or on stands ОР-

6687М. Valve face or cylinder head socket face shall be covered with paste, prepared with

one of the following compositions:

boron carbide M40 – 10%; microcorundum M20 – 90%;

granular electrocorundum M14 – 87%; paraffin – 13%;

The solution is dissolved in diesel oil to reach sour cream state. To increase quality it is

recommended to add oleinic or stearinic fatty acid.

Continue to grind until continuous dull string-course with width not less than 1,5 mm

appears on valve face or on valve seat face, breakage of the strip and scratch marks are not

admitted. Width variation of the string-course shall not exceed 0,5 mm.

After grinding valves and head shall be washed.

Atomizing nozzle

Combustion

chamber axis

- Table of Content 2

- 61

- 4 - plug; 65

- 4 – washer; 5 – nut 70

- Atomizing nozzle 81

- Combustion 81

- 245S3A М – 0000100 РЭ 87

- Annex B (referential) 89

- Annex E (referential) 92

- Annex F 94

- (obligatory dimension) 96

Comments to this Manuals